About

Recently, there has been growing interest in developing optical fiber networks to support the increasing bandwidth demands of multimedia applications. The internet also has stimulated an tremendous increase in the demand for various services, leaving the current infrastructure unable to keep up with its growing demands.

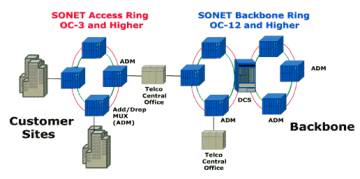

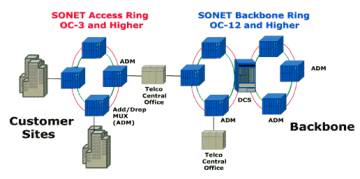

Fig. 1.1 shows the architecture of SONET (Synchronous Optical Network) [1]. There exists DCS (Digital Crossconnect) between SONET rings. The OEO (Optical to Electrical to Optical) conversion is needed in DCS, which is a bottleneck in large bandwidth system. Thus all optical network that uses OXC (Optical Crossconnect) instead of DCS is required.Conventional planar waveguide switches used in OXC has the problems of high loss and large size. A Free space optical switch with low loss and small size can be made by arrays of MEMS (Micro Electro Mechanical System) micromirrors.

Fig. 1.1 shows the architecture of SONET (Synchronous Optical Network) [1]. There exists DCS (Digital Crossconnect) between SONET rings. The OEO (Optical to Electrical to Optical) conversion is needed in DCS, which is a bottleneck in large bandwidth system. Thus all optical network that uses OXC (Optical Crossconnect) instead of DCS is required.Conventional planar waveguide switches used in OXC has the problems of high loss and large size. A Free space optical switch with low loss and small size can be made by arrays of MEMS (Micro Electro Mechanical System) micromirrors.

Figure 1.1 SONET ring structure

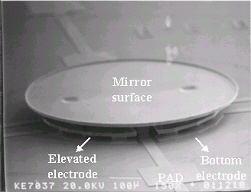

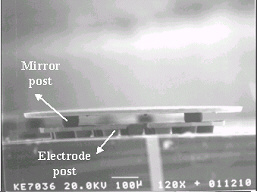

A new MEMS micromirror structure has been designed and fabricated for 3-D optical crossconnect. By analytic calculation and simulations, the actuation angles of the proposed micromirror have been estimated. The device has been fabricated by electroplating Cu using photoresist as a mold. To make a five layer mirror structure, double MESD ( Multi Expose Single Development ) has been used. The MESD process is the proprietary MEMS process developed at KAIST semiconductor research laboratory. Polishing has been added at the end of process to enhance the surface flatness and roughness of the fabricated micromirrors. Fig. 1.2a and 1.2b are the SEM pictures of fabricated micromirror. The fabricated mirror structure has been characterized with a 3-D profiler and AFM to measure the actuation angle and surface roughness. Surface flatness of 0.88 ¥ìm and roughness of 120 A have been acquired, respectively. Maximum actuation angle of 2.65o at 244 V has been measured. Fig. 1.3 shows comparison graphs of analytic calculation, MEMCAD simulation and experimental data after fabrication.

Figure 1.2a Slanted view of micromirror

Figure 1.2b Side view of micromirror

Figure 1.3 Comparison graph of calculation, simulation and measurement

Related Publications

- Ji-Hyuk Kim, Hyung-Kew Lee, Byung-Il Kim, Jin-Wan Jeon, Jun-Bo Yoon and Euisik Yoon, "A High Fill-Factor Micro-Mirror Stacked on a Crossbar Torsion Spring for Electrostatically- Actuated Two-Axis Operation in Large-Scale Optical Switch Array," will be presented at IEEE International MEMS conference 2003, Kyoto, Japan.