About

The Nucleic Acid (NA) probe assays typically include PCR to amplify the number of copies of DNA to a detectable level.

The PCR technique requires a relatively pure DNA sample in aqueous solution, free of inhibitors during the PCR process.

Therefore, the extraction and purification of nucleic acids from biological samples are the critical steps that should be carefully handled

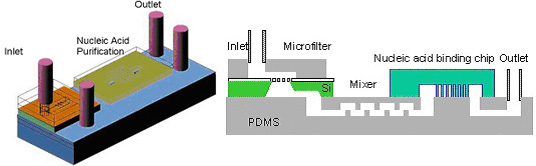

in the NA assays. In this work we have proposed a new microfluidic chip to address this sample preparation process for NA probe assays.The proposed microfluidic system is composed of three parts: microfilter, micromixer and DNA purification chip. In the microfilter, red blood cells are separated from whole blood sample. In the mixer, the plasma blood sample is mixed with lysis reagents to release the DNA into the solution and the lysed solution is mixed with chaotropic salt. In the DNA purification chip, the DNA’s in the solution will bind to the exposed SiO2 surface at a high concentration of chaotropic salt. After DNA has been adequately extracted in the binding process, wash solutions flow through the microchannel of the chip to wash away the remaining sample fluid. Finally, the DNA can be eluted from the chip by flowing through appropriate chemical buffer solutions.

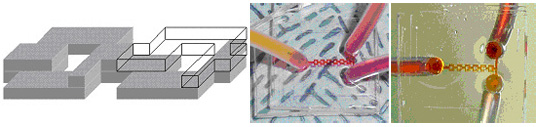

Figure 1. Schematic diagram of the proposed microfluidic system for sample preparation of Nucelic acid probe assay.

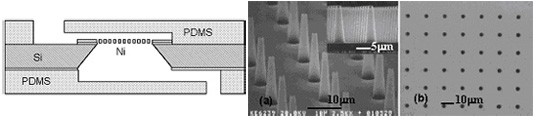

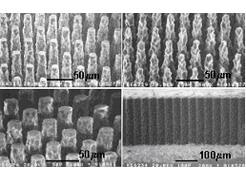

Figure 1. Schematic diagram of the proposed microfluidic system for sample preparation of Nucelic acid probe assay.- Microfilter using metallic microsieves

- Passive micromixer in three dimensional microchannels

- DNA purification chip on photosensitive glass

Related Publications

- Joon-Ho Kim, Byoung-Gyun Kim, Hyukjun Nam, Dae-Eun Park, Kwang-Seok Yun, Jun-Bo Yoon, Jichang You and Euisik Yoon, "A Disposable DNA Sample Preparation Microfluidic Chip for Nucleic Acid Probe Assay", IEEE International MEMS Conference 2002, Las Vegas, USA, Jan., 2002.

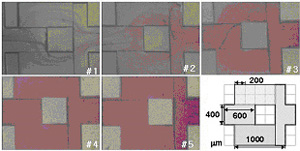

(a)

(a)

(b)

(b)

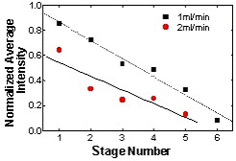

(a)

(a) (b)

(b)

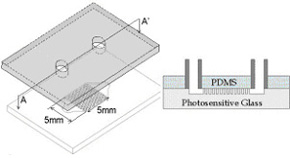

(a)

(a)

(b)

(b)